During the manufacturing, transportation and installation of the boiler, rust, welding slag and silicide will be formed, and impurities such as dust, sand and cement will also enter the boiler.At the same time, the steam drum, downcomer, convection tube and economizer tube of the newly installed boiler water circulation system cannot be cleaned by blowing and washing. The presence of these impurities will cause great harm to the operation of the boiler.

View more+

In the boiler feed water treatment process, deoxygenation is a very critical link. Oxygen is the main corrosive substance in the boiler feed water system. The oxygen in the feed water system should be removed quickly, otherwise it will corrode the boiler feed water system and components.

View more+

Descaling refers to the removal of impurities and sediments in boiler water to maintain stable water quality.Boiler feed water contains impurities such as dissolved salts and suspended matter, which will concentrate and deposit at high temperatures. Deterioration of water quality will lead to scaling and corrosion, affecting the safe operation of the boiler.

View more+

The core component of the boiler economizer is the heat exchanger, which can recycle and utilize the waste heat generated during the operation of the boiler.

View more+

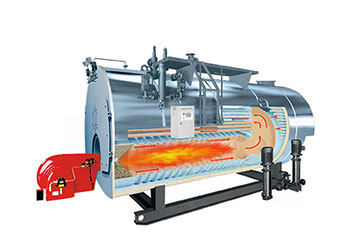

As an important equipment in industrial production, the operating efficiency and safety of boilers are crucial to the production process.In boiler design, the return path refers to the path that the flue gas follows inside the boiler.

View more+

The fuel required by biomass boilers is divided into two types: molded fuel and bulk fuel.Bulk fuel mainly includes all discarded crops such as straw, rice straw, firewood, wood chips, peanut shells,

View more+